LEDs have been the focus of many researches in the last years. Advancements in efficiency was one of the drivers for these continuous researches, since LEDs can transform energy to light and heat in more efficiently than current systems like HPS. LEDs can also be configured into new light spectrums, which makes precise light recipes per crop possible. Researches have been set up at Demokwekerij Westland, where commercial growers actively participated in the development of the light system. From this input, a list of requirements for artificial light was made. The requirements for a light system from a growers’ perspective: more light, small fixture, interaction with day light, minimal maintenance costs and able to communicate with climate computer.

Cooperation with Demokwekerij Westland

This input, along with the cooperation between Demokwekerij Westland and the commercial growers was the foundation for the development of the CLX V1000. Climalux created an innovative system which emits a spectrum similar to daylight, which requires considerably less energy and increases production. The fan, mounted in the fixture, acts as an active cooling element but can also be used to create an active, vertical air flow. Next to that, each individual fixture can be monitored and steered from a distance, which can be used to optimize settings and to perform maintenance.

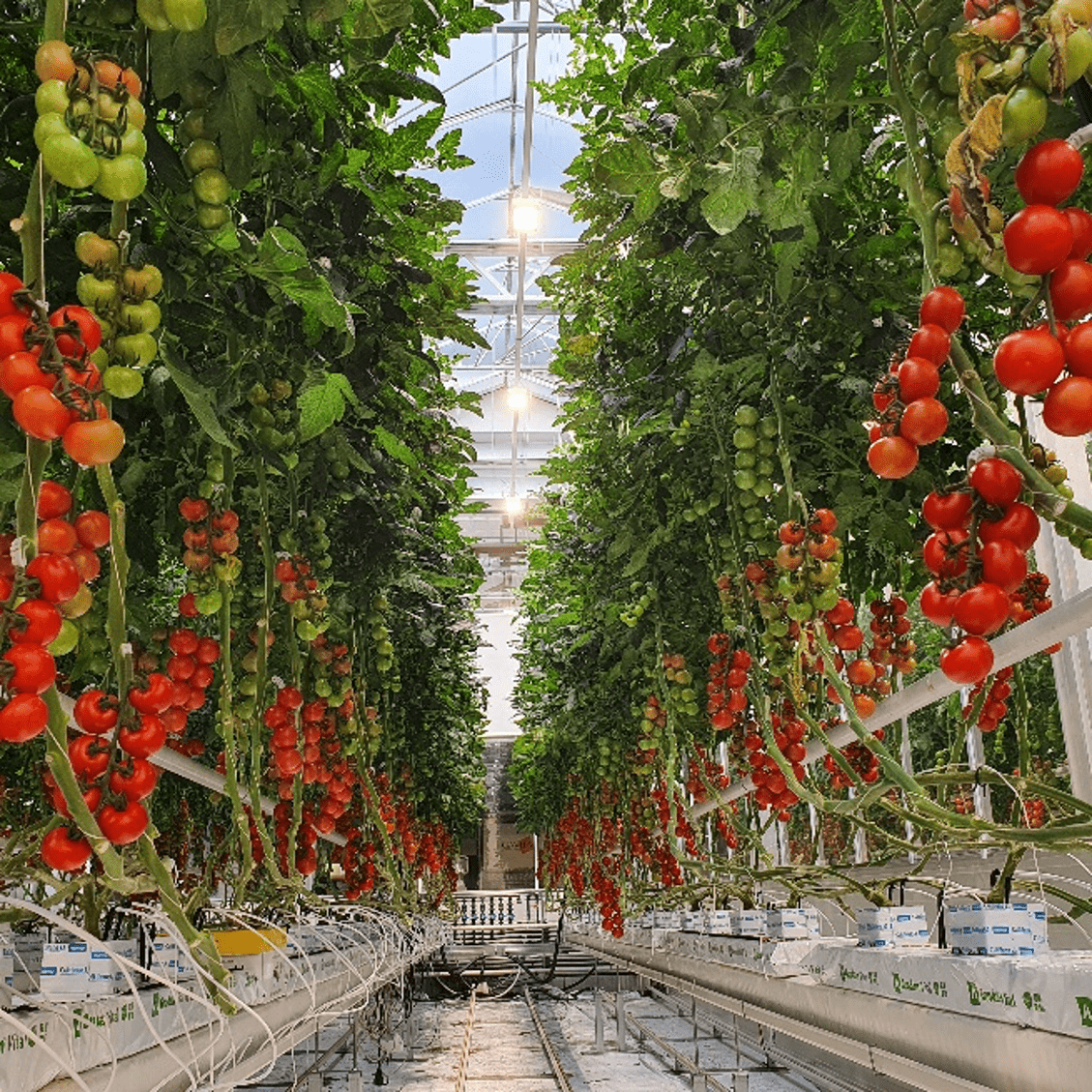

HortiTech is currently executing performance and demonstration researches for Climalux, together with renowned growers, at the World Horti Center in Naaldwijk, The Netherlands. The complete growing cycle for both cucumbers and tomatoes is being researched and documented, to show how the CLX V1000 performs in a practical growing environment.

Artificial grow light more powerful than ever

The specifications are something to behold. The CLX V1000 is a very powerful artificial light source, which can operate without the use of supplemental light and can be used on a variety of greenhouse crops. Next to that, the light source can be controlled and maintained from a distance, with dimming capabilities from 100% to 0% being present. These specifications make creating an even, balanced climate more feasible.

The integrated fan with control system, which can be operated even when the LED light source is inactive, gives the possibility to transfer the heat created by the light fixture towards the crop. The active ventilation capability means cooling in summer and heating in winter is possible. The fans create a vertical airflow, different to the horizontal airflow usually present in greenhouses. The vertical airflow creates a balanced microclimate and moisture balance, which in turn reduces the need for crop protection methods and boosts yields.

The combination of light, air and heat movement creates new pathways in how to steer crops. The tools created by the CLX V1000 align perfectly with the principles behind Plant Empowerment. With these specifications, the compact lamp, made of mostly Dutch components and assembled in The Netherlands, is more efficient and powerful than ever before.